Company History & Milestones

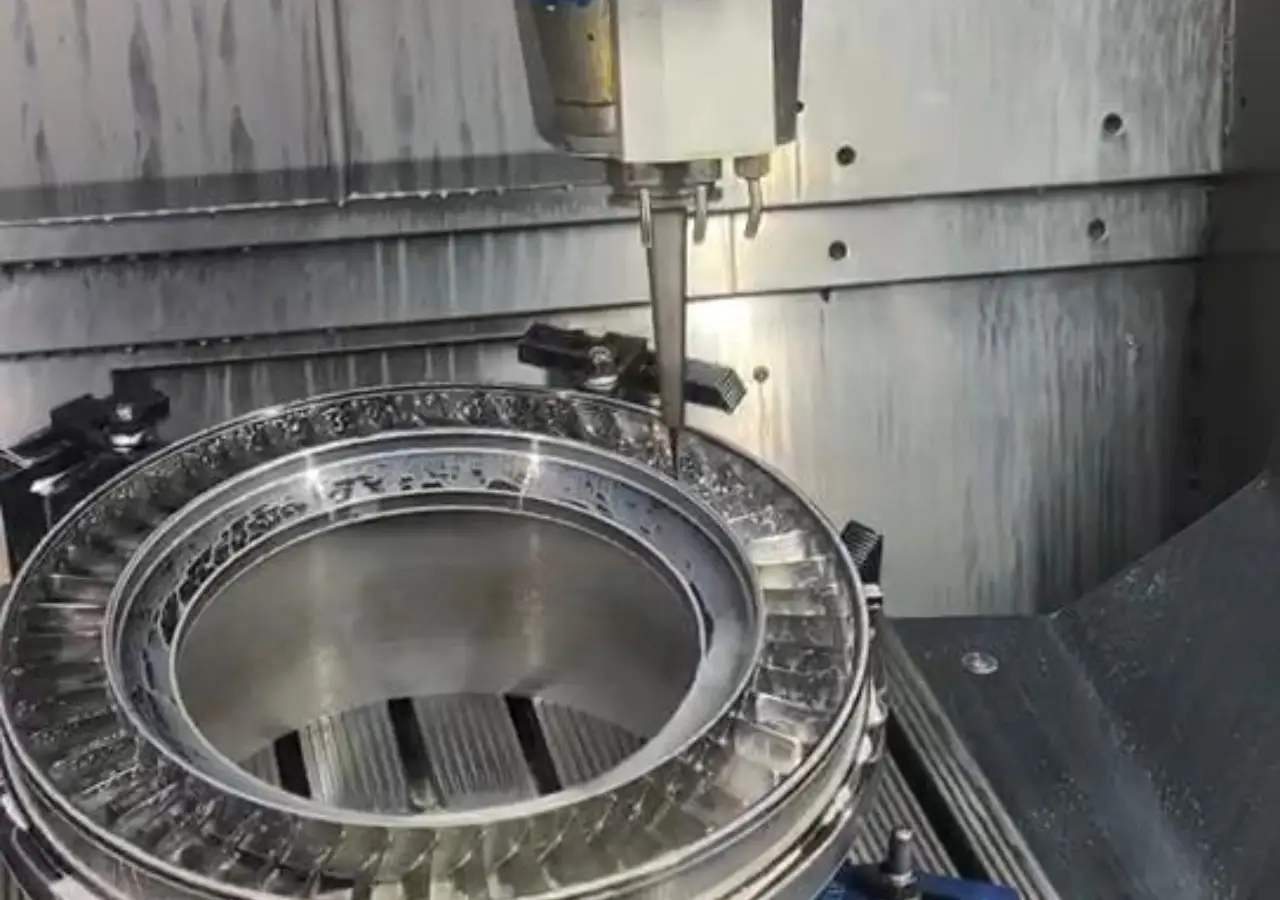

As a leading provider of CNC machining services since 2009, BEST Precision combines cutting-edge metal CNC machine technology with ISO 9001-certified processes. We specialize in high-tolerance CNC machined parts for medical, aerospace, and automation industries, offering end-to-end solutions from CNC cutting to complex assembly. With 14+ years serving global machining companies, our 3,000㎡ facility delivers custom CNC machining with 95-100% on-time delivery.

2010: Dongguan HQ founded: High-mix CNC prototyping & mid-volume production.

2015: Latina Tech Center: EU customer engineering support & R&D.

2019: Hunan Facility: Heavy machining & sheet metal operations.