ISO 9001:2015 | AS9100D | ITAR Registered

Professional CNC Machining Services - Precision Metal & Plastic Parts Manufacturing

Get instant quotes on custom CNC machining services. From rapid prototyping to full-scale production, we deliver precision-machined metal and plastic parts with tolerances to ±0.001 inch. ISO 9001:2015 and AS9100D certified with lead times as fast as 1 day.

Trusted by 1,000+ Companies for Precision CNC Machining Services

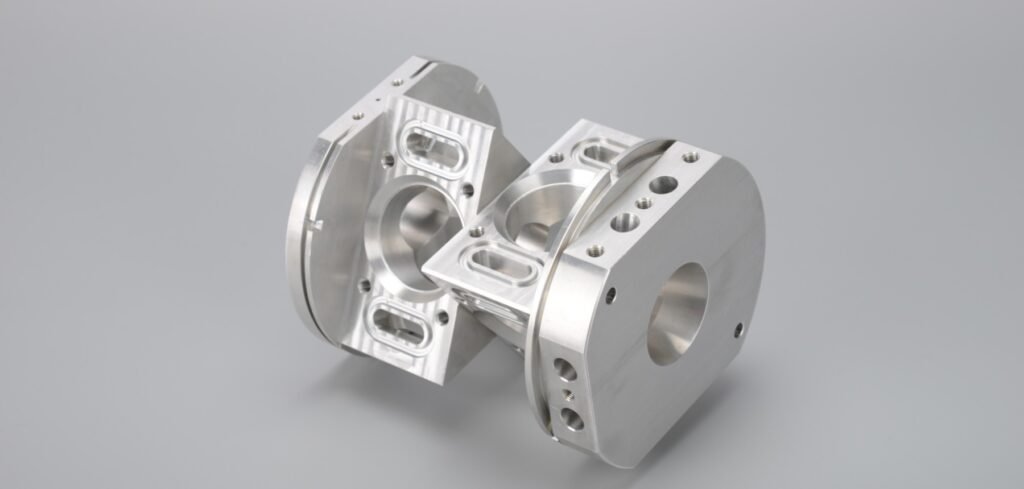

From aerospace manufacturers requiring complex CNC machine parts with tolerances to ±0.001 inch, to medical device companies needing biocompatible precision machining parts, over 1,000 companies worldwide trust our CNC machining services for their most critical manufacturing needs. Our reputation is built on consistently delivering exceptional quality across every project, whether producing a single prototype CNC machining part or manufacturing 100,000+ production components.

What sets us apart is our unwavering commitment to precision, speed, and customer satisfaction. Every CNC precision machining part that leaves our facility undergoes rigorous quality inspection using advanced metrology equipment, ensuring dimensional accuracy and surface finish specifications are met or exceeded. Our customers choose us because we understand that their success depends on reliable manufacturing partners who can deliver complex geometries, maintain tight tolerances, and meet aggressive deadlines without compromising quality.

With ISO 9001:2015, AS9100D, ISO 13485, and IATF 16949 certifications, we serve diverse industries including aerospace, medical devices, automotive, electronics, and industrial equipment. Our 98% on-time delivery rate and 4.9/5 customer satisfaction rating reflect our dedication to excellence in every aspect of CNC machining services, from initial quote to final delivery.

What is CNC Machining?

Comprehensive precision manufacturing solutions for your industry

Computer Numerical Control (CNC) machining is a subtractive manufacturing process that utilizes computer-controlled machines to create custom parts and components from solid blocks of material. This highly automated manufacturing technology is capable of producing parts with extremely tight tolerances and complex geometries, making it an essential cornerstone of modern precision manufacturing across diverse industries worldwide.

Our CNC machining services leverage state-of-the-art equipment including 3-axis, 4-axis, and 5-axis milling centers, precision CNC lathes and turning centers, high-speed routers, and advanced EDM machines. From aerospace and defense to medical devices and automotive components, CNC machining provides the unmatched precision, repeatability, and production speed necessary to bring innovative product designs to life while maintaining the highest quality standards.

With over 700 CNC machines in our manufacturing network and a team of experienced engineers and machinists, we can handle projects of any scale – from single prototype parts to high-volume production runs of 100,000+ units. Our instant quoting engine provides real-time pricing and design-for-manufacturability feedback, enabling you to optimize your designs for cost-effectiveness and production efficiency before committing to manufacturing.

Tolerances down to ±0.001″ (±0.025mm) with advanced metrology and quality control systems

100+ metals, plastics, and composites including aluminum, steel, titanium, PEEK, and carbon fiber

Lead times as fast as 1 day for urgent projects with 24/7 manufacturing capabilities

Core Advantages of Our CNC Machining Services

Expert Engineering Support

Our team of experienced manufacturing engineers provides comprehensive design-for-manufacturability (DFM) analysis and optimization recommendations. We work collaboratively with your team to identify cost-saving opportunities, improve part quality, and ensure your designs are optimized for production. Free DFM feedback is included with every quote.

- Free DFM Analysis

- Expert Engineers

- 24/7 Support

Ultra-Fast Turnaround

Standard lead times of 3-5 business days with expedited 1-day production available for urgent projects. Our 24/7 manufacturing operations and optimized production scheduling ensure your parts are delivered on time, every time. Free standard shipping on all US orders.

- 1-day expedited service

- 24/7 production capability

- Free US shipping

Extensive Manufacturing Network

- 3 owned facilities

- 700+ CNC machines

- 10,000+ partners

Certified Quality Systems

ISO 9001:2015, AS9100D, ISO 13485, and IATF 16949:2016 certified manufacturing facilities with comprehensive quality management systems. Every part undergoes rigorous inspection using advanced metrology equipment including CMM, optical comparators, and precision gauges.

- Multi-industry certifications

- 100% inspection available

- Full traceability & CoC

Welcome! Here is our CNC machining center in Dongguan

This video walks you through our Dongguan CNC workshop. Our technicians are using advanced CNC equipment to drill, turn, and mill parts with micron-level accuracy, followed by grinding or polishing for perfect surfaces.

CNC Machining Services Categories

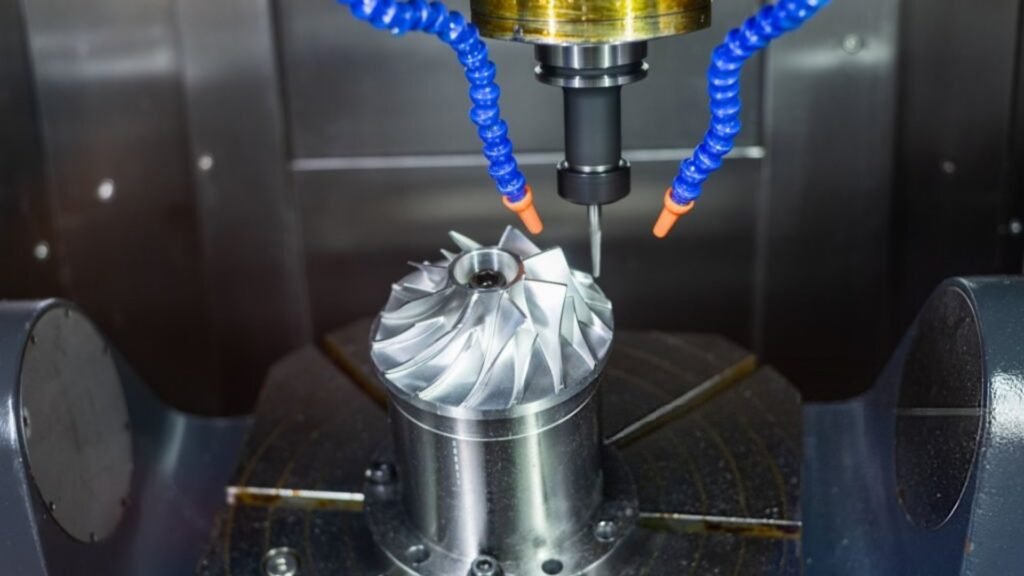

5 Axis CNC Machining Services

Advanced CNC Milling Services

Our advanced 3-axis, 4-axis, and 5-axis CNC milling centers can produce complex shapes, intricate features, and high-tolerance components with exceptional precision and surface finish quality. This versatile process is ideal for creating everything from simple prismatic parts to complex multi-faceted aerospace components with tight geometric tolerances.

With over 200 CNC milling centers in our manufacturing network, including high-speed machining centers and heavy-duty machines for large parts, we have the capacity and expertise to handle milling projects of any scale and complexity. Our milling capabilities support parts up to 80″ × 48″ × 24″ with tolerances down to ±0.001 inch.

Capabilities:

- 3-axis, 4-axis, 5-axis milling

- High-speed machining (HSM)

- Complex 3D geometries

- Tight tolerances (±0.001″)

Materials:

- Aluminum alloys

- Stainless steel

- Titanium alloys

- Engineering plastics

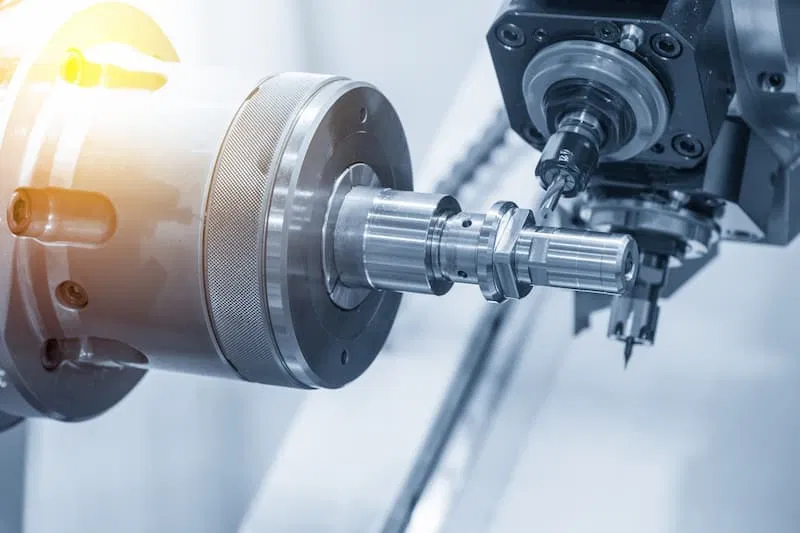

Precision CNC Turning Services

Our CNC lathes and turning centers are engineered for producing cylindrical parts, shafts, bushings, and rotational components with extremely tight tolerances and superior surface finishes. With live tooling capabilities, we can perform secondary milling, drilling, and threading operations in a single setup, significantly reducing lead times while improving dimensional accuracy and concentricity.

Our turning capabilities include both standard CNC lathes and advanced Swiss-type turning centers for high-precision small parts. We can handle parts from 0.5″ to 32″ in diameter and up to 62″ in length, with production volumes from single prototypes to millions of parts annually.

Capabilities:

- CNC lathe turning

- Swiss-type machining

- Live tooling operations

- Thread cutting & knurling

Applications:

- Shafts & spindles

- Bushings & sleeves

- Threaded components

- Precision pins

EDM & Wire EDM Services

Electrical Discharge Machining (EDM) and Wire EDM are specialized non-traditional machining processes that use precisely controlled electrical sparks to cut and shape conductive materials. These advanced methods are ideal for creating intricate features, sharp internal corners, micro-holes, and complex cavities in very hard materials that are extremely difficult or impossible to machine with conventional cutting tools.

Our EDM capabilities include both sinker EDM for complex 3D cavities and wire EDM for precise 2D profiles and through-cuts. We regularly machine hardened tool steels, carbide, Inconel, and other exotic alloys for tooling, aerospace, and medical device applications requiring exceptional precision and surface integrity.

Capabilities:

- Sinker EDM

- Wire EDM

- Micro-hole drilling

- Sharp internal corners

Applications:

- Injection mold tooling

- Hardened steel parts

- Carbide components

- Aerospace parts

High-Speed CNC Routing Services

For larger flat-sheet materials including plastics, composites, aluminum, and wood, our high-speed CNC routers provide an efficient and cost-effective solution for cutting complex 2D and 3D shapes, profiles, and pockets. Perfect for signage, fixtures, large-format parts, and composite components that require precise edge quality and dimensional accuracy.

Our CNC routing capabilities include both 3-axis and 5-axis routers with work envelopes up to 10′ × 5′, enabling us to process large sheets and panels efficiently. We specialize in acrylic, polycarbonate, HDPE, carbon fiber, and other composite materials commonly used in aerospace, marine, and industrial applications.

Capabilities:

- Large format routing

- 3D contouring

- Nesting optimization

- V-grooving & engraving

Materials:

- Acrylic & polycarbonate

- Carbon fiber composites

- Aluminum sheet

- Wood & MDF

Our CNC Machining Capabilities: Technical Specifications & Tolerances

Specification Category | Parameter | Details & Capabilities |

CNC Milling Capabilities | Maximum Part Size | 3-Axis Milling: up to 80″ × 48″ × 24″ (2032 × 1219 × 610 mm) 4-Axis Milling: up to 60″ × 40″ × 30″ (1524 × 1016 × 762 mm) 5-Axis Milling: up to 60″ × 40″ × 30″ (1524 × 1016 × 762 mm) |

Minimum Feature Size | 0.020″ (0.50 mm) with standard tooling 0.010″ (0.25 mm) with micro-machining capabilities 0.005″ (0.13 mm) for specialized applications | |

Standard Tolerances | Metals: ±0.005″ (±0.127 mm) or ±0.002″/inch, whichever is greater Plastics: ±0.010″ (±0.254 mm) or ±0.003″/inch, whichever is greater | |

Precision Tolerances | ±0.002″ (±0.051 mm) for critical dimensions ±0.001″ (±0.025 mm) with advanced inspection ±0.0005″ (±0.013 mm) for ultra-precision features | |

Surface Finish | As-Machined: 125 Ra (3.2 μm) typical Fine Machining: 63 Ra (1.6 μm) Precision Machining: 32 Ra (0.8 μm) Polished: 16 Ra (0.4 μm) or better | |

CNC Turning Capabilities | Maximum Part Diameter | Standard Lathes: up to 32″ (813 mm) diameter Large Capacity: up to 48″ (1219 mm) diameter |

Maximum Part Length | Standard Lathes: up to 62″ (1575 mm) Swiss-Type: up to 12″ (305 mm) with ⌀0.5″ to 1.5″ diameter | |

Concentricity | ±0.001″ (±0.025 mm) TIR typical ±0.0005″ (±0.013 mm) TIR for precision work | |

Thread Specifications | Internal threads: M2 to M100 (metric), #4-40 to 4″ (imperial) External threads: M3 to M120 (metric), #6-32 to 5″ (imperial) Thread classes: 1A/1B to 3A/3B, 4H to 8H | |

EDM Capabilities | Wire EDM Wire Diameter | 0.004″ to 0.012″ (0.10 to 0.30 mm) |

Wire EDM Accuracy | ±0.0002″ (±0.005 mm) positional accuracy ±0.0001″ (±0.0025 mm) repeatability | |

Sinker EDM Cavity Depth | Up to 16″ (406 mm) deep cavities | |

EDM Surface Finish | 8 Ra (0.2 μm) to 125 Ra (3.2 μm) depending on requirements | |

Production & Lead Times | Standard Lead Time | 3-5 business days from order confirmation Includes manufacturing, inspection, and finishing |

Expedited Service | 1-2 business days available for urgent projects Same-day quotes for rush evaluation | |

Production Capacity | Prototyping: 1-10 parts Low Volume: 10-100 parts Medium Volume: 100-1,000 parts High Volume: 1,000-100,000+ parts | |

Materials & Finishes | Metals Available | Aluminum Alloys: 6061-T6, 7075-T6, 2024-T3, 5052-H32, MIC-6 Stainless Steel: 303, 304/304L, 316/316L, 17-4 PH, 15-5 PH, 420 Steel: 1018, 1045, 4140, 4340, A36, A2, D2, O1, H13 Titanium: Grade 2 (CP), Grade 5 (Ti6Al4V), Grade 23 (Ti6Al4V ELI) Exotic Alloys: Inconel 625/718, Hastelloy, Monel, Invar 36, Kovar Copper Alloys: C110 Copper, Brass (C360, C260), Bronze (C932, C954) |

Plastics Available | Engineering Plastics: Delrin (Acetal), Nylon 6/6, PEEK, Ultem (PEI), PTFE (Teflon) Commodity Plastics: ABS, Polycarbonate, Acrylic (PMMA), PVC, HDPE, PP High-Performance: Torlon, Vespel, PPSU, Radel, G-10/FR4 | |

Surface Finishes | Anodizing: Type II (0.0002″-0.001″), Type III Hard Coat (0.001″-0.004″) Plating: Electroless Nickel, Zinc, Chrome, Gold, Silver Coating: Powder Coating (2-4 mils), E-Coating, Teflon Coating Mechanical: Bead Blasting, Tumbling, Polishing, Brushing Heat Treatment: Annealing, Stress Relieving, Hardening, Tempering | |

Quality & Inspection | Inspection Equipment | CMM: Zeiss, Mitutoyo (accuracy to ±0.0001″) Optical Comparator: 10X to 50X magnification Surface Roughness Tester: Mitutoyo Surftest Hardness Tester: Rockwell, Brinell, Vickers Calipers & Micrometers: Digital, ±0.0001″ resolution |

Inspection Standards | First Article Inspection (FAI) per AS9102 PPAP Level 1-5 for automotive IQ/OQ/PQ for medical devices | |

Quality Certifications | ISO 9001:2015 (Quality Management) AS9100D (Aerospace) ISO 13485:2016 (Medical Devices) IATF 16949:2016 (Automotive) ITAR Registered (Defense) | |

Documentation | Certificate of Conformance (CoC) Material Test Reports (MTR) Dimensional Inspection Reports Material Certifications (Mill Certs) PPAP Documentation First Article Inspection Reports (FAIR) | |

File Formats & Design | CAD File Formats | Preferred: STEP (.step, .stp), IGES (.igs, .iges), Parasolid (.x_t) Supported: SOLIDWORKS (.sldprt), ACIS (.sat), STL (.stl), Inventor (.ipt), CATIA, Creo/Pro-E |

2D Drawing Formats | PDF, DWG, DXF (for reference and GD&T callouts) | |

Design Review | Free automated DFM analysis with every quote Engineering review for complex parts Tolerance stack-up analysis available | |

Tolerancing Standards | Geometric Tolerancing | Full GD&T per ASME Y14.5-2018 ISO 1101 geometric tolerancing Position, perpendicularity, flatness, parallelism, concentricity, runout |

Hole Tolerances | Drilled Holes: ±0.005″ (±0.127 mm) Reamed Holes: ±0.001″ (±0.025 mm) Bored Holes: ±0.0005″ (±0.013 mm) | |

Angular Tolerances | ±0.5° standard ±0.25° precision ±0.1° ultra-precision |

Comprehensive CNC Machining Materials: Metals, Plastics & Composites

Metal Alloys

Aluminum alloys 6061 and 7075 stand out as premier choices for precision CNC machining due to their exceptional lightweight properties combined with an excellent strength-to-weight ratio and superior machinability. These alloys offer outstanding corrosion resistance, making them indispensable for aerospace components where weight reduction is critical, automotive parts requiring durability and performance, consumer electronics demanding precise tolerances, and protective enclosures that must withstand environmental challenges while maintaining structural integrity.

Stainless steel grades 304, 316L, and 17-4 PH deliver uncompromising performance through their high strength characteristics, exceptional corrosion resistance, and superior heat resistance properties, ensuring long-lasting durability in demanding applications. These versatile alloys are the material of choice for critical medical devices requiring biocompatibility, food processing equipment where hygiene is paramount, and marine hardware that must withstand harsh saltwater environments while maintaining structural reliability and performance over extended periods.

Alloy steel and carbon steel varieties provide exceptional high strength, outstanding wear resistance, and remarkable toughness, making them the backbone of heavy-duty industrial applications. These robust materials are specifically engineered for manufacturing precision jigs and fixtures that require dimensional stability, industrial machinery components that must withstand continuous operation under load, and automotive components where strength and reliability are non-negotiable requirements for safety and performance.

Brass and copper materials offer unparalleled electrical conductivity combined with excellent corrosion resistance and superior machinability, making them essential for applications requiring both electrical performance and precision manufacturing. These materials are specifically chosen for electrical connectors where reliable conductivity is critical, plumbing fittings that must resist corrosion while maintaining leak-proof seals, and decorative hardware applications where both functional performance and aesthetic appeal are equally important.

Titanium represents the ultimate in advanced material engineering, delivering an exceptional strength-to-weight ratio, outstanding corrosion resistance, and unique biocompatible properties that make it irreplaceable in the most demanding applications. This premium material is specifically selected for aerospace components where every gram matters without compromising strength, medical implants requiring perfect biocompatibility with human tissue, and high-performance applications where conventional materials simply cannot meet the extreme requirements for strength, weight, and environmental resistance.

Plastic

ABS plastic delivers exceptional high impact strength combined with outstanding toughness and rigidity, making it an ideal choice for applications requiring durability and structural integrity. This versatile thermoplastic excels in rapid prototyping where design validation is critical, protective enclosures that must withstand mechanical stress and environmental conditions, and consumer products where both performance and cost-effectiveness are essential. The excellent balance of mechanical properties and processability makes ABS particularly valuable for manufacturers seeking reliable material performance in demanding applications while maintaining economic viability for both prototype development and volume production.

Nylon polyamide stands out as a premium engineering plastic offering high mechanical strength, exceptional wear resistance, and superior chemical resistance, making it indispensable for high-performance mechanical applications. This robust material is specifically engineered for precision gears that require consistent performance under load, bearings that must operate smoothly over extended periods, bushings that demand low friction and wear characteristics, and structural components where mechanical reliability is paramount. The unique combination of strength, durability, and chemical stability makes nylon the material of choice for applications where conventional plastics cannot meet the demanding requirements of continuous mechanical operation.

Polycarbonate plastic provides remarkable high impact strength and excellent toughness while maintaining optical transparency, creating unique opportunities for applications requiring both structural performance and visual clarity. This exceptional material is specifically selected for precision lenses where optical clarity and impact resistance are equally critical, safety guards that must provide protection while allowing visibility, and electronic housings that require both electromagnetic shielding and visual access to internal components. The rare combination of mechanical strength, optical properties, and dimensional stability makes polycarbonate invaluable for applications where traditional materials cannot simultaneously meet structural and optical requirements.

POM Delrin® delivers exceptional high stiffness, ultra-low friction characteristics, and outstanding dimensional stability, making it the premier choice for precision mechanical components requiring tight tolerances and smooth operation. This advanced engineering plastic is specifically designed for precision gears where accurate tooth profiles and consistent performance are essential, high-performance bearings that must operate with minimal friction and wear, precision rollers requiring smooth surface finish and dimensional accuracy, and critical mechanical assemblies where dimensional stability under varying environmental conditions is non-negotiable. The superior machinability and exceptional dimensional control make POM ideal for applications demanding the highest levels of precision and reliability.

PEEK represents the pinnacle of high-performance engineering plastics, offering exceptional high-temperature performance, outstanding chemical resistance, and superior mechanical strength that rivals many metals while maintaining the processing advantages of thermoplastics. This premium material is specifically engineered for demanding aerospace components where weight reduction and temperature resistance are critical, biocompatible medical implants requiring long-term stability in biological environments, and precision semiconductor equipment where chemical purity and dimensional stability at elevated temperatures are essential. The unique combination of thermal stability, chemical inertness, and mechanical performance makes PEEK the ultimate choice for applications where conventional materials simply cannot meet the extreme requirements of modern high-technology industries.

Professional CNC Machining Surface Finishes & Post-Processing Services

The standard finish with visible tool marks from CNC machining operations. Surface roughness typically ranges from 125-250 μin Ra. This cost-effective option maintains original material properties and dimensional accuracy while providing immediate availability upon machining completion. Perfect for prototypes, internal components, and applications where surface texture is not critical to functionality or aesthetics.

Creates uniform matte or satin surface finishes by removing machining marks through controlled abrasive media. Achieves 32-125 μin Ra surface roughness while providing complete coverage on complex geometries. This process improves fatigue resistance, enhances paint adhesion, and creates ideal surface preparation for subsequent coatings. Excellent for consumer electronics, automotive trim, and architectural hardware requiring uniform appearance.

Transforms aluminum surfaces into durable, corrosion-resistant ceramic coatings with extensive color options. Type II provides decorative finishes with excellent corrosion resistance, while Type III delivers hard-coat protection with superior wear resistance up to 700 HV hardness. Both types offer integral coating that cannot chip or peel, making them essential for aerospace, medical, automotive, and consumer electronics applications.

Electrostatic coating process delivering exceptional durability and unlimited color options. Creates 0.002″-0.008″ thick finish with superior impact, scratch, and chemical resistance. Environmentally friendly with zero VOCs and 99% transfer efficiency. Available in smooth, textured, metallic, and special effect finishes with temperature resistance up to 400°F. Perfect for outdoor equipment, architectural components, and consumer appliances requiring long-term durability.

Progressive abrasive process creating smooth, reflective surfaces from rough polish (32 μin Ra) to super mirror finish (<1 μin Ra). Removes surface imperfections while maintaining tight tolerances on complex geometries. Compatible with stainless steel, aluminum, brass, and exotic alloys. Essential for optical components, medical instruments, food processing equipment, and high-end consumer products where surface quality impacts performance or aesthetics.

Electroplating process applying metallic coatings for enhanced corrosion resistance and surface hardness. Options include nickel (wear resistance, magnetic shielding), chrome (up to 1000 HV hardness, low friction), zinc (sacrificial corrosion protection), and specialty platings like copper, tin, silver, and gold. Critical for automotive components, electronic connectors, hydraulic systems, and applications requiring enhanced surface properties beyond base materials.

CNC Machining Design Guidelines: DFM Best Practices for Cost Optimization

1. Avoid Deep Pockets and Cavities

Keep pocket depths less than 4× the tool diameter. Deeper pockets require specialized long tools that are prone to deflection and breakage, increasing cost and reducing accuracy.

2. Use Standard Hole Sizes

Specify standard drill sizes whenever possible. Custom hole sizes require special tooling or multiple operations, significantly increasing cost.

3. Add Internal Corner Radii

CNC tools are round, so internal corners will have a radius. Design with corner radii matching standard tool sizes (typically 0.125″ or 3mm minimum) to avoid costly EDM operations.

4. Limit Thread Depth

Keep threaded holes to a maximum depth of 3× the diameter. Deeper threads require special taps and increase the risk of tool breakage.

5. Maintain Uniform Wall Thickness

Thin walls (< 0.020″ or 0.5mm) are prone to deflection and vibration during machining. Maintain minimum wall thickness of 0.030″ (0.75mm) for metals and 0.060″ (1.5mm) for plastics.

Design Assistance for CNC Machining Services

Leverage our decades of machining expertise with free design consultation and DFM analysis. We’ll help you optimize part geometry, tolerances, and material selection for maximum manufacturability. Start your project now.

CNC Machining Industry Applications & Manufacturing Solutions

Why Choose Us

50% to 100% lower than Europe and America

ISO9001:2015 certified and committed to continuous improvement

Your Parts Delivery in as fast as 3 days

From inquiries to issues, our team provides you 24/7 instant support

From metals to plastics, meets your every requirement for precision and quality

Plating, anodizing, heat treating, powder coating, and other finishing processes,tailored to your needs

Speed up your product development with quick, accurate prototypes

15 years serving European and American clients, tolerances down to +/- 0.001

Every part is carefully wrapped and secured, preventing any potential damage during transportation

How We Ensure Accurate, On-Time CNC Machining Parts Delivery

To ensure your order is processed accurately and delivered on time, your part design is thoroughly reviewed before production begins. All specifications, including materials and surface finish, are carefully checked to prevent any issues. Throughout manufacturing, in-process inspections are performed to maintain consistent quality and precision. After production, a final inspection is conducted, and your parts are carefully packaged to ensure safe delivery. With this rigorous process, your parts are guaranteed to meet high-quality standards and be delivered on time, providing you with peace of mind.

Your part design will be reviewed by our engineering team, including 3D/2D drawings, material, surface finish, and structure. Any necessary adjustments or optimizations will be communicated promptly to address potential issues before production begins.

You will receive parts made from the highest quality raw materials, carefully selected to meet your exact specifications. Certification reports with material details, grades, and properties are available upon request, ensuring transparency and confidence in your order.

Your parts are manufactured using advanced CNC Turning, Milling, and Grinding equipment, ensuring precision and accuracy. With in-house machinery and high-precision testing tools, we guarantee top-quality results for even the most complex designs.

First article and in-process inspections are conducted to ensure your parts meet design and quality standards. Continuous monitoring during production ensures precision and compliance with your specifications, guaranteeing high-quality results.

Before shipment, all your parts are inspected for critical dimensions, tolerances and appearance. Then they are carefully packaged to prevent damage during transit, and inspection reports are provided upon request, ensuring your parts meet your standards.

Certified Quality Standards for Professional CNC Machining Services

Client Testimonial

SEE WHAT OUR CUSTOMERS SAY ABOUT US?

Real Feedback, Real Results: Hear directly from our clients about the exceptional quality and service we provide with every project we deliver.

Frequently Asked Questions

Get answers to common questions about our CNC Machining services

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a solid workpiece, shaping it into a desired form. The process begins with a 3D CAD model, which is converted into machine instructions (G-code) using CAM software. The CNC machine then precisely follows these instructions to cut, drill, mill, or turn the material with exceptional accuracy and repeatability. CNC machining is known for its high precision, versatility in working with various materials, and ability to produce complex geometries.

The cost of CNC machining depends on several factors including part complexity, material selection, quantity, tolerance requirements, surface finish, and lead time. Simple parts in common materials like aluminum 6061 can cost as little as $50-100, while complex parts in exotic materials like titanium or Inconel can cost several hundred to thousands of dollars. Our instant quoting engine provides real-time pricing based on your specific design and requirements. Generally, higher quantities result in lower per-part costs due to economies of scale. To get the most accurate pricing, upload your CAD file to receive an instant quote with no obligation.

We can hold standard tolerances of ±0.005 inch (±0.127mm) for metals and ±0.010 inch (±0.254mm) for plastics and composites. For projects requiring higher precision, we can achieve tolerances as tight as ±0.001 inch (±0.025mm) upon request and design review. Ultra-precision tolerances down to ±0.0005 inch (±0.013mm) are possible for critical features using specialized equipment and processes. However, tighter tolerances increase cost and lead time, so we recommend only specifying tight tolerances on critical dimensions. Our engineering team can help you determine the appropriate tolerances for your application during the DFM review process.

Our standard lead time is 3-5 business days from order confirmation to shipment. However, we offer expedited production options and can deliver parts in as fast as 1 day for urgent projects, depending on the complexity, quantity, and material availability. Lead times may vary based on part complexity, quantity, material selection, and finishing requirements. Simple parts in common materials typically ship faster than complex parts requiring specialized processes. All US orders include free standard shipping, with expedited shipping options available. You’ll receive real-time lead time estimates when you upload your CAD file and configure your order.

We can machine over 100 different metals, plastics, and composites. Popular metals include aluminum alloys (6061-T6, 7075-T6, 2024, 5052), stainless steel (303, 304, 316/316L, 17-4 PH), steel (1018, 4140, 4340, A2, O1), titanium (Grade 2, Grade 5), brass, copper, and exotic alloys like Inconel, HASTELLOY, and Invar. Common plastics include ABS, Delrin (Acetal/POM), nylon, polycarbonate, PEEK, PTFE (Teflon), Ultem (PEI), acrylic, and HDPE. We also machine composites like carbon fiber, FR4, and G-10 garolite. If you don’t see your desired material listed, please contact us and our team will work to source it for you.

Yes, we provide comprehensive quality documentation including Certificates of Conformance (CoC), material certifications, inspection reports, and First Article Inspection Reports (FAIR) upon request. Our facilities are certified to ISO 9001:2015, AS9100D (aerospace), ISO 13485 (medical devices), and IATF 16949:2016 (automotive). We are also ITAR registered for defense-related projects. All parts can be inspected using our advanced metrology equipment including CMM, optical comparators, and precision gauges. Full traceability is available from raw material to finished part, meeting the stringent requirements of aerospace, medical, and defense industries.

We accept all major CAD file formats including: STEP (.step, .stp), IGES (.iges, .igs), Parasolid (.x_t, .x_b), ACIS (.sat), SolidWorks (.sldprt, .sldasm), Inventor (.ipt, .iam), CATIA (.catpart, .catproduct), Creo/Pro-E (.prt, .asm), and neutral formats. For best results, we recommend STEP or Parasolid formats. You can also provide 2D drawings in PDF or DWG format.

Yes, we offer comprehensive finishing services including deburring, surface treatments, heat treating, anodizing, plating, and protective coatings. Our goal is to deliver finished parts ready for your application, reducing your supply chain complexity and ensuring consistent quality throughout the process.

We have no minimum order quantity. Whether you need a single prototype or thousands of production parts, we can accommodate your needs with competitive pricing.

Absolutely! Our instant quoting engine provides automated design-for-manufacturability (DFM) feedback when you upload your CAD file, identifying potential issues such as thin walls, deep pockets, sharp internal corners, and undercuts. Our experienced manufacturing engineers are also available to provide detailed DFM reviews and optimization recommendations at no additional cost. We can suggest design modifications to reduce machining time, improve part strength, lower costs, and ensure your parts are manufacturable to the highest quality standards. Simply upload your file or contact our engineering team to get started.

Still have questions? Our engineering team is here to help.

Related Manufacturing Services

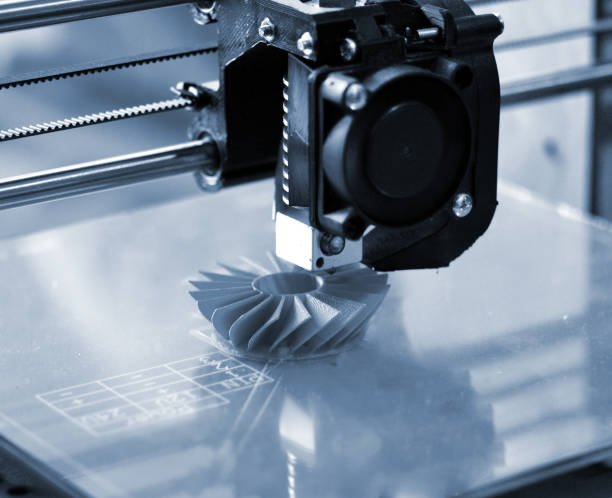

Rapid prototyping with FDM, SLA, SLS, and metal 3D printing. Fast turnaround additive manufacturing for prototypes and low-volume production. Over 50 materials including plastics, resins, and metals.

Laser cutting, bending, welding, and finishing services. Custom sheet metal parts and assemblies with laser cutting, CNC bending, welding, and powder coating. Ideal for enclosures and brackets.

Maximize efficiency with our complete manufacturing ecosystem: expert assembly services, custom plastic parts production, advanced rapid prototyping, and scalable solutions for both low-volume and high-volume production requirements.

Ready to Start Your CNC Machining Project?

Upload your CAD file now to get an instant quote, free DFM analysis, and competitive pricing for your custom precision-machined parts. Join over 1,000+ satisfied customers worldwide.