Best Machining

Professional 5-Axis CNC Machining Services

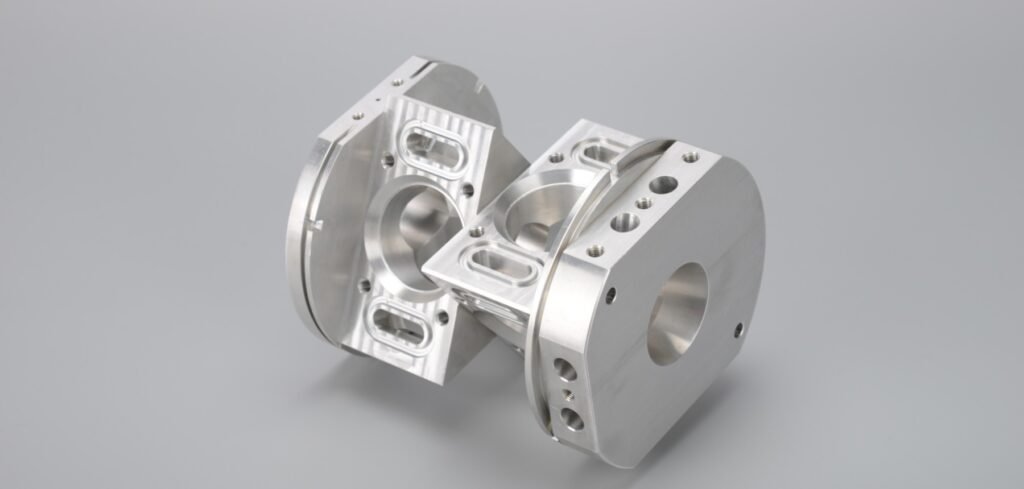

Transform complex designs into precision parts with our advanced 5-axis CNC machining capabilities. From aerospace components to medical devices, we deliver exceptional qualitywith Tolerances to ±0.0001″ | 50+ Materials | Expert Engineering Support | Free DFM Analysis

Industry Leaders Choose Our 5-Axis CNC Machining Services: 1,000+ Satisfied Clients

What is 5-Axis CNC Machining?

5-axis CNC machining represents the pinnacle of computer-controlled manufacturing technology. Unlike traditional 3-axis machines that move along X, Y, and Z axes, 5-axis machines add two rotational axes (typically A and B or C), enabling the cutting tool to approach the workpiece from virtually any direction.

This revolutionary capability allows manufacturers to create highly complex geometries in a single setup, including undercuts, compound angles, and organic shapes that would be impossible or prohibitively expensive with conventional machining methods.

Our state-of-the-art 5-axis CNC machining centers are equipped with advanced control systems, high-speed spindles (up to 20,000 RPM), and precision positioning (±0.0002″ accuracy), making them ideal for demanding applications in aerospace, medical devices, automotive, and industrial sectors.

Complete complex parts in one operation

Tolerances to ±0.0001 inch

Machine from any angle

Ra 4-32 μin surface quality

Core Advantages of 5-Axis CNC Machining

Single Setup Manufacturing

Complete complex parts in one operation, eliminating multiple setups and reducing errors by up to 40%. This results in higher accuracy, faster production, and significant labor cost savings.

Unmatched Precision

Achieve tolerances as tight as ±0.0001″ (±0.0025mm) with exceptional repeatability. Our CMM inspection ensures every dimension meets your exact specifications for critical aerospace and medical applications.

50-70% Faster Production

Reduce cycle times dramatically compared to 3-axis machining. Simultaneous 5-axis movement and optimized tool paths enable rapid production without compromising quality.

Lower Total Cost

Despite higher machine costs, 5-axis machining reduces overall expenses through fewer setups, minimal fixturing, reduced labor, lower scrap rates, and faster turnaround times.

Complex Geometry Freedom

Machine undercuts, compound angles, deep cavities, and organic shapes that are impossible with 3-axis. Enable innovative designs without manufacturing constraints.

Superior Surface Finish

Achieve mirror-like finishes (Ra 4 μin) with optimal tool orientation. Better surface quality reduces or eliminates secondary finishing operations, saving time and cost.

Types of 5-Axis CNC Machining

Simultaneous 5-Axis Machining

All five axes move simultaneously during cutting operations, enabling the creation of highly complex organic shapes and sculptured surfaces.

Ideal Applications:

- Aerospace turbine blades and impellers

- Medical implants with organic geometries

- Automotive molds and dies

- Sculptured surfaces and artistic components

- Complex propeller and fan blades

Key Benefits:

- Best surface finish quality (Ra 4-16 μin)

- Shortest cycle times for complex parts

- Optimal tool engagement angles

- Reduced tool wear and longer tool life

Indexed 5-Axis Machining

Rotational axes position the part, then lock in place while 3-axis machining occurs. More economical for parts requiring multiple angled features.

Ideal Applications:

- Multi-sided prismatic parts

- Angled holes and pockets

- Valve bodies and manifolds

- Brackets with compound angles

- Fixtures and tooling components

Key Benefits:

- More cost-effective than simultaneous

- Easier programming and setup

- Excellent for angled features

- Faster than multiple 3-axis setups

5-Axis vs 3-Axis CNC Machining Comparison

| Feature | 3-Axis Machining | 5-Axis Machining |

|---|---|---|

| Axes of Movement | X, Y, Z (linear only) | X, Y, Z + 2 rotational (A, B or C) |

| Part Complexity | Simple to moderate geometries | Highly complex, organic shapes |

| Setup Requirements | Multiple setups (3-6 typical) | Single setup for most parts |

| Precision & Accuracy | ±0.001″ typical | ±0.0001″ achievable |

| Cycle Time | Baseline | 50-70% faster |

| Surface Finish | Ra 63-125 μin | Ra 4-32 μin |

| Tool Access | Limited to vertical approach | 360° access to workpiece |

| Best For | Planar parts, simple pockets | Complex contours, undercuts |

5-Axis CNC Machining Technical Specifications & Capabilities

| Specification Category | Parameter | Capability | Notes |

|---|---|---|---|

| Tolerance Capabilities | Standard Precision | ±0.001″ (±0.025mm) | General production parts |

| High Precision | ±0.0001″ (±0.0025mm) | Aerospace & medical components | |

| Ultra-Precision | ±0.00005″ (±0.00127mm) | Critical features, tight-tolerance applications | |

| Size Capabilities | Maximum Part Size | 60″ × 40″ × 30″ (1524 × 1016 × 762mm) | Large aerospace structural components |

| Minimum Feature Size | 0.010″ (0.25mm) | Micro-machining capabilities | |

| Maximum Part Weight | 500 lbs (227 kg) | Heavy-duty machining capacity | |

| Rotary Axis Range | A-axis: ±120°, C-axis: 360° | Full 5-axis simultaneous capability | |

| Surface Finish Quality | Standard Finish | Ra 32 μin (0.8 μm) | General industrial applications |

| Fine Finish | Ra 16 μin (0.4 μm) | Precision components, reduced post-processing | |

| Mirror Polish | Ra 4 μin (0.1 μm) | Medical implants, optical components | |

| Custom Finishes | As-machined to Ra 2 μin | Specialty applications, upon request | |

| Machining Performance | Spindle Speed | Up to 20,000 RPM | High-speed machining for aluminum & plastics |

| Positioning Accuracy | ±0.0002″ (±0.005mm) | Repeatability across all 5 axes | |

| Tool Magazine Capacity | 40-60 tools | Complex parts without tool changes | |

| Production Lead Times | Prototypes (1-10 parts) | 5-10 business days | Rapid prototyping service |

| Small Production (10-100 parts) | 2-4 weeks | Bridge production runs | |

| Medium Production (100-500 parts) | 4-8 weeks | Full production capability | |

| Rush Service | 3-7 days | Expedited processing available | |

| Quality & Certifications | ISO Certification | ISO 9001:2015 | Quality management system |

| Aerospace Certification | AS9100D | Aerospace quality standards | |

| Inspection Equipment | Zeiss CMM, Optical Comparators | Full dimensional inspection | |

| Environmental Control | ±1°F (±0.56°C) stability | Climate-controlled manufacturing | |

| Equipment & Technology | Machine Brands | Haas, Mazak, DMG MORI | Industry-leading 5-axis centers |

| CAM Software | Mastercam, Siemens NX, Hypermill | Advanced 5-axis programming | |

| Thermal Compensation | Active thermal management | Maintains accuracy during long runs |

5-Axis CNC Machining Materials

Our 5-axis CNC machining services support an extensive range of 50+ engineering-grade metals, alloys, and high-performance plastics specifically selected for demanding aerospace, medical device, automotive, and industrial applications. The advanced multi-axis capabilities of our 5-axis machining centers enable us to work with challenging materials that require precise tool orientation, optimal cutting angles, and superior surface finishes—materials that are often difficult or impossible to machine effectively with traditional 3-axis equipment. From difficult-to-machine exotic alloys like Inconel 718 and Hastelloy used in aerospace turbine components, to biocompatible titanium Grade 23 for medical implants, to high-performance engineering plastics like PEEK and Ultem for demanding industrial applications, our 5-axis technology provides the geometric freedom and tool access required to achieve exceptional results. Our material experts understand the unique machining characteristics, optimal cutting parameters, and post-processing requirements for each material, ensuring we select and machine the perfect material for your specific performance, regulatory compliance, and cost requirements. Whether you need corrosion-resistant stainless steel for marine applications, lightweight aluminum alloys for aerospace structures, or FDA-compliant plastics for medical devices, our 5-axis CNC machining capabilities deliver precision parts in the exact material your application demands.

Metal Alloys

Aluminum alloys 6061 and 7075 stand out as premier choices for precision CNC machining due to their exceptional lightweight properties combined with an excellent strength-to-weight ratio and superior machinability. These alloys offer outstanding corrosion resistance, making them indispensable for aerospace components where weight reduction is critical, automotive parts requiring durability and performance, consumer electronics demanding precise tolerances, and protective enclosures that must withstand environmental challenges while maintaining structural integrity.

Stainless steel grades 304, 316L, and 17-4 PH deliver uncompromising performance through their high strength characteristics, exceptional corrosion resistance, and superior heat resistance properties, ensuring long-lasting durability in demanding applications. These versatile alloys are the material of choice for critical medical devices requiring biocompatibility, food processing equipment where hygiene is paramount, and marine hardware that must withstand harsh saltwater environments while maintaining structural reliability and performance over extended periods.

Alloy steel and carbon steel varieties provide exceptional high strength, outstanding wear resistance, and remarkable toughness, making them the backbone of heavy-duty industrial applications. These robust materials are specifically engineered for manufacturing precision jigs and fixtures that require dimensional stability, industrial machinery components that must withstand continuous operation under load, and automotive components where strength and reliability are non-negotiable requirements for safety and performance.

Brass and copper materials offer unparalleled electrical conductivity combined with excellent corrosion resistance and superior machinability, making them essential for applications requiring both electrical performance and precision manufacturing. These materials are specifically chosen for electrical connectors where reliable conductivity is critical, plumbing fittings that must resist corrosion while maintaining leak-proof seals, and decorative hardware applications where both functional performance and aesthetic appeal are equally important.

Titanium represents the ultimate in advanced material engineering, delivering an exceptional strength-to-weight ratio, outstanding corrosion resistance, and unique biocompatible properties that make it irreplaceable in the most demanding applications. This premium material is specifically selected for aerospace components where every gram matters without compromising strength, medical implants requiring perfect biocompatibility with human tissue, and high-performance applications where conventional materials simply cannot meet the extreme requirements for strength, weight, and environmental resistance.

Plastic

ABS plastic delivers exceptional high impact strength combined with outstanding toughness and rigidity, making it an ideal choice for applications requiring durability and structural integrity. This versatile thermoplastic excels in rapid prototyping where design validation is critical, protective enclosures that must withstand mechanical stress and environmental conditions, and consumer products where both performance and cost-effectiveness are essential. The excellent balance of mechanical properties and processability makes ABS particularly valuable for manufacturers seeking reliable material performance in demanding applications while maintaining economic viability for both prototype development and volume production.

Nylon polyamide stands out as a premium engineering plastic offering high mechanical strength, exceptional wear resistance, and superior chemical resistance, making it indispensable for high-performance mechanical applications. This robust material is specifically engineered for precision gears that require consistent performance under load, bearings that must operate smoothly over extended periods, bushings that demand low friction and wear characteristics, and structural components where mechanical reliability is paramount. The unique combination of strength, durability, and chemical stability makes nylon the material of choice for applications where conventional plastics cannot meet the demanding requirements of continuous mechanical operation.

Polycarbonate plastic provides remarkable high impact strength and excellent toughness while maintaining optical transparency, creating unique opportunities for applications requiring both structural performance and visual clarity. This exceptional material is specifically selected for precision lenses where optical clarity and impact resistance are equally critical, safety guards that must provide protection while allowing visibility, and electronic housings that require both electromagnetic shielding and visual access to internal components. The rare combination of mechanical strength, optical properties, and dimensional stability makes polycarbonate invaluable for applications where traditional materials cannot simultaneously meet structural and optical requirements.

POM Delrin® delivers exceptional high stiffness, ultra-low friction characteristics, and outstanding dimensional stability, making it the premier choice for precision mechanical components requiring tight tolerances and smooth operation. This advanced engineering plastic is specifically designed for precision gears where accurate tooth profiles and consistent performance are essential, high-performance bearings that must operate with minimal friction and wear, precision rollers requiring smooth surface finish and dimensional accuracy, and critical mechanical assemblies where dimensional stability under varying environmental conditions is non-negotiable. The superior machinability and exceptional dimensional control make POM ideal for applications demanding the highest levels of precision and reliability.

PEEK represents the pinnacle of high-performance engineering plastics, offering exceptional high-temperature performance, outstanding chemical resistance, and superior mechanical strength that rivals many metals while maintaining the processing advantages of thermoplastics. This premium material is specifically engineered for demanding aerospace components where weight reduction and temperature resistance are critical, biocompatible medical implants requiring long-term stability in biological environments, and precision semiconductor equipment where chemical purity and dimensional stability at elevated temperatures are essential. The unique combination of thermal stability, chemical inertness, and mechanical performance makes PEEK the ultimate choice for applications where conventional materials simply cannot meet the extreme requirements of modern high-technology industries.

5-Axis CNC Machining Surface Finishes

Our advanced 5-axis CNC machining technology delivers superior surface finishes (Ra 4-32 μin) directly from the machine through optimal tool orientation and continuous multi-axis movement, significantly reducing or eliminating secondary finishing operations. We offer comprehensive post-machining surface treatments including anodizing, electroplating, powder coating, bead blasting, and polishing specifically optimized for 5-axis machined components in aerospace, medical device, and precision industrial applications. The geometric freedom of 5-axis machining enables consistent surface quality across complex contours, undercuts, and sculptured surfaces that are difficult or impossible to achieve with traditional 3-axis equipment, ensuring your parts meet both functional performance and aesthetic requirements.

The standard finish with visible tool marks from CNC machining operations. Surface roughness typically ranges from 125-250 μin Ra. This cost-effective option maintains original material properties and dimensional accuracy while providing immediate availability upon machining completion. Perfect for prototypes, internal components, and applications where surface texture is not critical to functionality or aesthetics.

Creates uniform matte or satin surface finishes by removing machining marks through controlled abrasive media. Achieves 32-125 μin Ra surface roughness while providing complete coverage on complex geometries. This process improves fatigue resistance, enhances paint adhesion, and creates ideal surface preparation for subsequent coatings. Excellent for consumer electronics, automotive trim, and architectural hardware requiring uniform appearance.

Transforms aluminum surfaces into durable, corrosion-resistant ceramic coatings with extensive color options. Type II provides decorative finishes with excellent corrosion resistance, while Type III delivers hard-coat protection with superior wear resistance up to 700 HV hardness. Both types offer integral coating that cannot chip or peel, making them essential for aerospace, medical, automotive, and consumer electronics applications.

Electrostatic coating process delivering exceptional durability and unlimited color options. Creates 0.002″-0.008″ thick finish with superior impact, scratch, and chemical resistance. Environmentally friendly with zero VOCs and 99% transfer efficiency. Available in smooth, textured, metallic, and special effect finishes with temperature resistance up to 400°F. Perfect for outdoor equipment, architectural components, and consumer appliances requiring long-term durability.

Progressive abrasive process creating smooth, reflective surfaces from rough polish (32 μin Ra) to super mirror finish (<1 μin Ra). Removes surface imperfections while maintaining tight tolerances on complex geometries. Compatible with stainless steel, aluminum, brass, and exotic alloys. Essential for optical components, medical instruments, food processing equipment, and high-end consumer products where surface quality impacts performance or aesthetics.

Electroplating process applying metallic coatings for enhanced corrosion resistance and surface hardness. Options include nickel (wear resistance, magnetic shielding), chrome (up to 1000 HV hardness, low friction), zinc (sacrificial corrosion protection), and specialty platings like copper, tin, silver, and gold. Critical for automotive components, electronic connectors, hydraulic systems, and applications requiring enhanced surface properties beyond base materials.

Design Assistance for 5 Axis CNC Machining Services

Our engineers review your 5-axis CNC machining designs to optimize manufacturability, reduce costs, and enhance precision for complex parts made from aluminum, titanium, stainless steel, and engineering plastics. We provide expert guidance on tolerances, tool paths, and part geometries to ensure your components fully leverage the advantages of 5-axis machining—such as multi-surface accessibility and superior accuracy—while avoiding common design and setup challenges.

We Supply 5-Axis CNC Machining Parts to Clients Across These Industries

Why Choose Us

50% to 100% lower than Europe and America

ISO9001:2015 certified and committed to continuous improvement

Your Parts Delivery in as fast as 3 days

From inquiries to issues, our team provides you 24/7 instant support

From metals to plastics, meets your every requirement for precision and quality

Plating, anodizing, heat treating, powder coating, and other finishing processes,tailored to your needs

Speed up your product development with quick, accurate prototypes

15 years serving European and American clients, tolerances down to +/- 0.001

Every part is carefully wrapped and secured, preventing any potential damage during transportation

How We Ensure Accurate, On-Time 5-Axis CNC Machining Parts Delivery

To ensure your order is processed accurately and delivered on time, your part design is thoroughly reviewed before production begins. All specifications, including materials and surface finish, are carefully checked to prevent any issues. Throughout manufacturing, in-process inspections are performed to maintain consistent quality and precision. After production, a final inspection is conducted, and your parts are carefully packaged to ensure safe delivery. With this rigorous process, your parts are guaranteed to meet high-quality standards and be delivered on time, providing you with peace of mind.

Your part design will be reviewed by our engineering team, including 3D/2D drawings, material, surface finish, and structure. Any necessary adjustments or optimizations will be communicated promptly to address potential issues before production begins.

You will receive parts made from the highest quality raw materials, carefully selected to meet your exact specifications. Certification reports with material details, grades, and properties are available upon request, ensuring transparency and confidence in your order.

Your parts are manufactured using advanced CNC Turning, Milling, and Grinding equipment, ensuring precision and accuracy. With in-house machinery and high-precision testing tools, we guarantee top-quality results for even the most complex designs.

First article and in-process inspections are conducted to ensure your parts meet design and quality standards. Continuous monitoring during production ensures precision and compliance with your specifications, guaranteeing high-quality results.

Before shipment, all your parts are inspected for critical dimensions, tolerances and appearance. Then they are carefully packaged to prevent damage during transit, and inspection reports are provided upon request, ensuring your parts meet your standards.

Uncompromising Precision: 5-Axis CNC Machining Quality Assurance Excellence

Client Testimonial

SEE WHAT OUR CUSTOMERS SAY ABOUT US?

Real Feedback, Real Results: Hear directly from our clients about the exceptional quality and service we provide with every project we deliver.

Frequently Asked Questions

Get answers to common questions about our 5-Axis CNC Machining services

5-axis CNC machining is an advanced manufacturing process that uses computer-controlled machines to move cutting tools across five different axes simultaneously (X, Y, Z linear axes plus two rotational axes). This allows for the creation of highly complex parts with intricate geometries in a single setup, eliminating the need for multiple repositioning operations and resulting in higher accuracy and better surface finish.

5-axis machining offers several key advantages: (1) Single-setup efficiency – complete complex parts in one operation, (2) Superior precision – achieve tolerances to ±0.0001″, (3) 50-70% faster cycle times, (4) Better surface finish (Ra 4-32 μin), (5) Ability to machine undercuts and compound angles, (6) Reduced labor costs and setup time, (7) Higher accuracy due to elimination of multiple setups.

We machine 50+ engineering-grade materials including: Aluminum alloys (6061, 7075, 2024, 5052), Stainless steel (303, 304, 316/316L, 17-4 PH), Titanium (Grade 2, Grade 5 Ti-6Al-4V), Steel (1018, 4140, 4340), Tool steel (D2, A2, O1), Specialty alloys (Inconel 625/718, Hastelloy, Monel), Copper alloys (brass, bronze), and Engineering plastics (PEEK, Ultem, Delrin, Nylon, Polycarbonate, ABS, Acrylic, PTFE).

We offer three levels of precision: Standard Precision (±0.001″ / ±0.025mm) for general applications, High Precision (±0.0001″ / ±0.0025mm) for critical dimensions, and Ultra-Precision (±0.00005″ / ±0.00127mm) for the most demanding aerospace and medical applications. Our positioning accuracy is ±0.0002″ (±0.005mm). All parts are inspected using CMM with full dimensional reports provided.

Lead times vary by project complexity and quantity: Prototypes (1-10 parts): 5-10 business days, Small production runs (10-100 parts): 2-4 weeks, Large production runs (100+ parts): 4-8 weeks. Rush services are available with delivery in as little as 3-7 days for urgent projects (additional fees apply). We provide accurate lead time estimates with every quote.

We accept all major CAD file formats including: STEP (.step, .stp), IGES (.iges, .igs), Parasolid (.x_t, .x_b), ACIS (.sat), SolidWorks (.sldprt, .sldasm), Inventor (.ipt, .iam), CATIA (.catpart, .catproduct), Creo/Pro-E (.prt, .asm), and neutral formats. For best results, we recommend STEP or Parasolid formats. You can also provide 2D drawings in PDF or DWG format.

Yes, we offer comprehensive finishing services including deburring, surface treatments, heat treating, anodizing, plating, and protective coatings. Our goal is to deliver finished parts ready for your application, reducing your supply chain complexity and ensuring consistent quality throughout the process.

We have no minimum order quantity. Whether you need a single prototype or thousands of production parts, we can accommodate your needs with competitive pricing.

We maintain ISO 9001:2015 for quality management, AS9100D for aerospace applications, ISO 13485 for medical devices, and IATF 16949 for automotive manufacturing. We’re also ITAR registered for defense applications. All certifications are regularly audited and maintained to ensure compliance with the most stringent industry standards.

Simultaneous 5-axis machining moves all five axes continuously during cutting, ideal for complex organic shapes, sculptured surfaces, and parts requiring the best surface finish. Indexed (3+2) 5-axis machining positions the rotational axes, locks them in place, then performs 3-axis machining – more economical for parts with angled features or multiple sides. We’ll recommend the best approach based on your part geometry and budget.

Still have questions? Our engineering team is here to help.

How 5-Axis CNC Machining Works

Related Manufacturing Services

Advanced CNC machining capabilities deliver precision milling and turning services for complex aerospace, medical, and automotive components. Our state-of-the-art equipment processes materials including aluminum, stainless steel, titanium, and engineering plastics with tolerances to ±0.0005". Complete inspection, material certifications, and engineering support ensure first-time-right quality for demanding applications.

High-precision CNC turning services for cylindrical parts, shafts, bushings, and threaded components. Swiss-type and conventional CNC lathes handle diameters from 0.125" to 12" with ±0.0005" tolerances and 16-32 μin Ra surface finishes. Process aluminum, brass, stainless steel, and engineering plastics. Fast prototyping (3-5 days) and production volumes with complete quality documentation.

Advanced CNC milling services with 3-axis, 4-axis, and 5-axis capabilities for complex geometries, pockets, and contoured surfaces. Achieve ±0.0005" tolerances, 16-63 μin Ra finishes, and machine aluminum, steel, titanium, and plastics. Vertical and horizontal machining centers handle parts up to 40" x 20" x 20". Engineering support and rapid prototyping available.

Ultra-precision Wire EDM for intricate profiles, tight internal corners, and hardened materials up to 65 HRC. Achieve ±0.0001" tolerances and Ra 8 μin surface finishes on complex 2D and tapered 4-axis geometries without mechanical cutting forces.

Ready to Get Started with 5-Axis CNC Machining?

Upload your CAD files today and receive a detailed quote with DFM analysis within 24 hours. Our expert engineers are ready to help bring your designs to life with precision and quality.